Apple is experimenting with 3D printing to produce upcoming smartwatches, which could signal a shift in the company's manufacturing process.

Stainless steel accounts for about 10% of Apple's watch production, and the company has traditionally used a traditional manufacturing process for these watches. Forging is used to shape material bricks into smaller blocks of metal that are close to the size of the watch, which is then cut by a computer numerical control (CNC) machine to create the device's specific design and button holes.

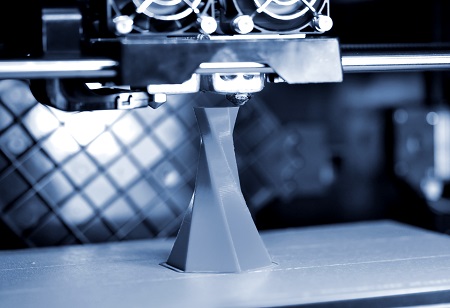

This new technique, which has been in development for about three years, uses binder jetting, a type of 3D printing, to create a device's general outline that is close to its actual size. This is used to create the near-net shape of a product. Sintering compresses the powder into a steel-like form, which is then milled for precise design and cutouts.

According to sources, the new 3D printing technique eliminates the need to cut large slabs of metal, which is currently required to manufacture products. Thus, the new technique would reduce material consumption and even production time, resulting in a more efficient manufacturing process and, thus an improved supply chain.

In the future, Apple may also 3D print iPhones.