Ford Motor Company intends to build a $3.5 billion factory in Michigan, employing at least 2,500 people, to produce lower-cost batteries for a variety of new and existing electric vehicles.

The plant, which would be built on industrial development land about 100 miles (160 kilometres) west of Detroit, would begin producing batteries in 2026. According to Ford, it would produce 35 gigatonnes of batteries per year, enough to power 400,000 vehicles.

The factory near Marshall would manufacture lithium-iron-phosphate (LFP) batteries, which are less expensive than the current nickel-cobalt-manganese chemistry used in many EV batteries.

Consumers could then choose between a battery with lower range and cost, or pay more for higher range and power. The company wouldn’t give any prices just yet.

“The whole intent here is to make EVs more affordable and accessible to customers," said Marin Gjaja, chief marketing officer for Ford’s electric vehicles.

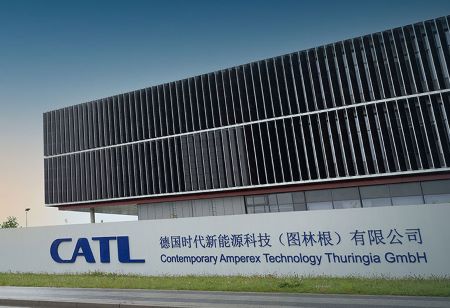

According to Ford, the factory would be owned and operated by a wholly owned subsidiary. However, Contemporary Amperex Technology Co. Limited, or CATL, a Chinese company known for its lithium-iron-phosphate expertise, would provide technology, some equipment, and workers.

The announcement comes at a time when relations between the United States and China are strained, and the Biden administration is offering tax breaks to businesses that establish a U.S. supply chain for EV batteries. Customers will not be able to receive the full $7,500 per vehicle U.S. tax credit if their EV batteries contain metals or components from China.

Ford is hoping that the deal's structure will deflect criticism of spending tax breaks on a joint-venture factory that will be partially owned by a Chinese company. Virginia dropped out of the race for the same Ford plant last month after Gov. Glenn Youngkin described it as a "front" for the Chinese Communist Party that would raise national security concerns. At the time, Virginia had not offered Ford any incentives.

Because the vehicles are manufactured in North America, the company expects to take advantage of U.S. factory tax credits, with buyers initially receiving at least $3,750 in tax credits. Gjaja stated that depending on the source, they could eventually receive the full $7,500 credit.

Lithium-iron-phosphate batteries would be used in standard-range Ford EVs. For example, the cheapest Mustang Mach-E electric SUV would have an LFP battery and be able to travel 247 miles per charge. The long-range Mach-E will have a nickel-cobalt-manganese chemistry that will allow it to travel 310 miles per charge.

The plant was unveiled Monday at a Michigan Strategic Fund meeting, which approved a large tax incentive package for the project near Interstates 94 and 69.

“We were looking not only in the U.S. We were looking outside of the U.S., as well," said Bill Ford, Ford Motor Co. executive chair. "There were a lot of places in play, because, as you can imagine, a lot of states and even countries would like this kind of investment. But Michigan really stepped up."

“I was always biased in favor of Michigan, because my family’s been here for generations," he added. "And I hope that will be true in the future, too. So, yeah, I feel very, very protective of Michigan. But they had to earn it, and they did."

SOAR, Michigan's Strategic Outreach and Attraction Reserve Fund, provided approximately $210 million. SOAR was established to attract industry and jobs to the state. However, the total value of the incentive package was not disclosed.

Since its inception in December 2021, the SOAR Fund has received nearly $1.8 billion from the state's general fund.

A tax-relief bill passed by the Michigan House last week could send up to $1.5 billion to the SOAR Fund over three fiscal years, in addition to the $800 million one-time deposit outlined by Gov. Gretchen Whitmer in her budget proposal last week.

Last summer, Ford announced that CATL will make lithium-iron-phosphate battery packs for Mustang Mach-E electric SUVs in North America this year and for F-150 Lightning electric trucks early in 2024. The batteries at first would come from China, then be switched to the Michigan plant in 2026, Ford said.

The company expects to be able to produce electric vehicles at a rate of 600,000 per year by late this year.

Whitmer said the plant will bring “generational opportunities" for west Michigan families. It will “make sure that production lines aren't stalled by global shocks or shipping delays," she said.

Lithium-iron-phosphate batteries already are in use in consumer electronics and some competitors’ vehicles, but all the batteries are imported, said Lisa Drake, vice president of industrialization for Ford’s electric vehicles.

“This project is aimed at de-risking that by actually building out the capacity and capability to scale this technology in the United States," with Ford controlling the manufacturing and the workforce.

Conrad Layson, senior analyst with AutoForecast Solutions, says the new battery factory could supply multiple Ford models. “As Ford increases the number of all-electric nameplates, the output from this factory could be used to make lower-cost versions of those future all-electric Ford vehicles," he said