Technology developments in the field of materials science and manufacturing have been fueled by the search for materials that are stronger, lighter, and more versatile. One of the most promising materials in this endeavour is carbon nanotubes (CNTs). These extraordinary nanostructures, made of carbon atoms organized in a cylindrical pattern, provide an exceptional balance of strength, lightness, and superior electrical and thermal properties. Carbon nanotubes are clearly paving the way for a revolution in manufacturing as researchers probe deeper into their possible applications.

Due to their exceptional strength and light weight, carbon nanotubes are perfect for usage in a wide range of products, including electronics, vehicles, and aircraft. They are excellent for usage in a range of sectors since they are also very corrosion-resistant. Overall, carbon nanotubes are an adaptable, strong material with the potential to completely transform a variety of sectors. The future of strong, lightweight materials in manufacturing is carbon nanotubes, as we shall see in the following section.

Unparalleled Strength-to-Weight Ratio

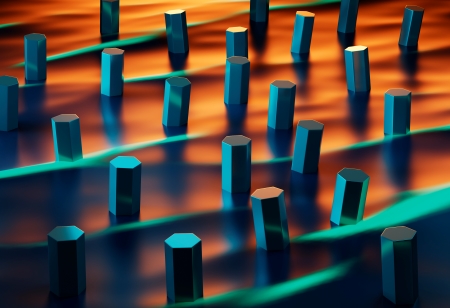

One of the most impressive attributes of carbon nanotubes is their unparalleled strength-to-weight ratio. This characteristic is a result of their unique atomic structure, in which carbon atoms are arranged in a hexagonal lattice to form a hollow cylindrical tube. This structure gives CNTs remarkable mechanical properties, making them incredibly strong while remaining exceptionally lightweight.

CNTs are, in fact, one of the strongest materials known to humanity. They can withstand enormous tensile forces without breaking, thanks to the covalent bonds between their carbon atoms. In practical terms, this means that CNTs can be used to reinforce and strengthen materials across various industries, including aerospace, automotive, and construction.

In aerospace, for instance, the demand for lightweight yet robust materials is ever-present. Carbon nanotubes have the potential to replace or augment traditional materials like aluminum and steel in aircraft construction. By incorporating CNT-reinforced composites into aircraft design, manufacturers can reduce overall weight, leading to increased fuel efficiency and lower operational costs. Furthermore, these materials can enhance structural integrity, reducing maintenance requirements and extending the lifespan of aircraft.

Similarly, the automotive industry can benefit significantly from carbon nanotubes. Vehicle weight directly impacts fuel efficiency and emissions. By utilizing CNTs in the production of automobile components, such as body panels and chassis, manufacturers can reduce vehicle weight without compromising safety or durability. This advancement can lead to more eco-friendly vehicles that consume less fuel and emit fewer greenhouse gases.

Exceptional Thermal and Electrical Conductivity

Beyond their remarkable strength, carbon nanotubes possess exceptional thermal and electrical conductivity properties. These attributes open up a wide range of possibilities for various manufacturing applications.

In the electronics industry, where miniaturization and efficiency are paramount, carbon nanotubes are a game-changer. Due to their excellent electrical conductivity, CNTs can serve as the building blocks for smaller and more powerful electronic components. They have the potential to replace traditional silicon transistors, which are approaching their physical limits in terms of miniaturization. This transition to CNT-based electronics could lead to faster and more energy-efficient devices, transforming industries like computing, telecommunications, and consumer electronics.

Moreover, the exceptional thermal conductivity of carbon nanotubes makes them ideal for thermal management applications. In manufacturing processes that generate significant heat, such as semiconductor fabrication or 3D printing, CNTs can be used to dissipate heat efficiently. This can extend the lifespan of equipment and improve overall manufacturing efficiency. Additionally, in the realm of renewable energy, CNTs can enhance the performance of photovoltaic cells and energy storage systems by improving heat dissipation and electrical conductivity.

"Carbon nanotubes have the potential to revolutionize many industries, from aerospace to electronics. Their remarkable strength and lightweight properties make them a material of the future." Says Dr. Richard Smalley, Nobel Laureate in Chemistry.

Versatility and Customizability

Another crucial aspect of carbon nanotubes is their versatility and customizability. CNTs come in various forms, including single-walled nanotubes (SWCNTs) and multi-walled nanotubes (MWCNTs), each with unique properties and applications. This versatility allows manufacturers to tailor CNTs to meet specific requirements in various industries.

For instance, SWCNTs are known for their exceptional electrical conductivity and are often employed in electronics, while MWCNTs are valued for their superior mechanical strength and are commonly used in reinforcing materials. By selecting the appropriate type of CNT, manufacturers can fine-tune the properties of their products to achieve the desired balance between strength, conductivity, and weight.

Additionally, carbon nanotubes can be functionalized and chemically modified to enhance their compatibility with specific materials or manufacturing processes. This flexibility allows for seamless integration into existing manufacturing methods, minimizing disruption while maximizing the benefits of CNTs.

An entirely new age in materials research and production is being ushered in by carbon nanotubes. CNTs offer a wide range of possibilities across industries thanks to their remarkable strength-to-weight ratio, exceptional thermal and electrical conductivity, and adaptability. The incorporation of carbon nanotubes promises to transform manufacturing processes, resulting in more effective, lighter, and stronger goods, whether in the aerospace, automotive, electronics, or renewable energy sectors.

We can anticipate even more ground-breaking uses to materialize as scientists continue to explore carbon nanotubes' potential and as manufacturing processes advance. The quest to fully utilize carbon nanotubes is ongoing, and it promises to reshape industries and spur innovation for years to come. Through the potential of carbon nanotubes, manufacturers, researchers, and engineers alike are set to play a crucial role in creating this future of light and robust materials.