Clarion Malaysia – has showcased its successful trial of Malaysia’s 5G-enabled advanced manufacturing line. It is one of the global automotive suppliers specializing in in-vehicle infotainment equipment. This trial was powered by YTL Communications’ Yes 5G Private Network and Cnergenz’s smart manufacturing solutions.

Gobind Singh, Malaysia's minister of Digital, remarked, “Clarion Malaysia’s collaboration with automation technologies from Cnergenz and Dassault Systèmes is a significant step in advancing Malaysia’s IR4.0 ambitions. 5G is not just for consumers; it will play a significant role in driving productivity and competitiveness for Malaysia.”

Tan Teong Khin, managing director of Clarion Malaysia, said, “The deployment of our AI-enabled smart factory is made possible by our partnership with Yes and Cnergenz, where their technical expertise and solution capabilities are pivotal in the implementation of this game-changing innovation.

Advanced manufacturing is revolutionizing the economic landscape of Asia, which has propelled the continent to new heights of growth and innovation. The integration of cutting-edge technologies, sustainability initiatives & supportive government policies is reshaping traditional manufacturing practices. These are making them more resilient, efficient, and competitive on the global stage. In this article let us explore the significant trends & real-time instances of how advanced manufacturing is bolstering growth in Asia.

“The manufacturing industry is widely regarded as a pivotal sector underpinning Asia’s economy. Over the past two decades, the region has evolved from a fledgling player in the global manufacturing landscape to an established international manufacturing hub,” says Sunny Chua General Manager at Wasabi Technologies, Singapore.

“India, for instance, has recently made headlines as the production hub for the latest iPhones, with Apple diversifying its supply chain to increase assembly in this key growth market,” he adds.

Advanced technologies & Industry 4.0

Automation & Robotics

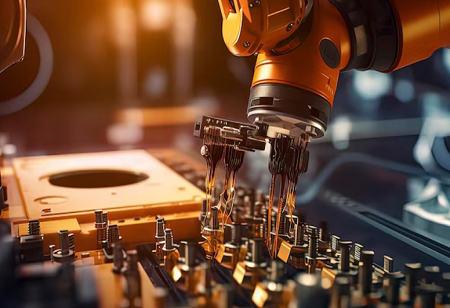

Automation & robotics are at the forefront of advanced manufacturing in Asia since the integration of robotics in manufacturing lines has improved efficiency & reduced labor costs to a great extent. For example, one of the largest manufacturers of robots in the world – China has been deploying robots across numerous industries which include electronics, automotive & consumer goods. Big players like Foxconn - one of the major suppliers for Apple have invested heavily in automation with an aim to enhance precision and decrease reliance on human labor.

Internet of Things

By enabling seamless communication between systems & machines, IoT is transforming manufacturing. Predictive maintenance, supply chain optimization & real-time monitoring are some of the IoT applications in manufacturing. IoT is used widely to improve efficiency as well as productivity in automotive & electronic industries in countries like Japan. Toyota, & Panasonic some of the manufacturing giants of Japan leverage IoT for streamlining operations & reducing downtime.

Additive manufacturing/3D printing

3D printing is another game changer in Asia as this technology facilitates rapid prototyping, customization as well as reduction in material waste. Industry leaders of South Korea like Samsung & LG leverage & incorporate 3D printing for manufacturing & product development. South Korea’s investment in R&D has positioned it as one of the leaders in advanced manufacturing technologies.

“Additive manufacturing is a trend we could not ignore. We had discussions with EDB on how to build the ecosystem together and we started to work with a research institute in Germany, where additive manufacturing is more developed, before building our own machines here in Singapore,” said Makino Asia CEO and President Mr Neo Eng Chong.

Workforce Development

Skill Development Programs

The move towards advanced manufacturing needs a skilled workforce that is capable of operating as well as maintaining new and advanced technologies. Many countries in the continent of Asia are investing heavily in education & training programs with an aim to equip workers with the necessary skills to improve their productivity and efficiency. For example, numerous vocational training centers have been established in China in order to upskill workers in the robotics & automation industry.

Collaboration with Academia

What is crucial for workforce development is the collaboration between academia & the industry and technical institutes & universities are partnering in countries like Japan and South Korea with manufacturing companies for rendering hands-on-training as well as research opportunities. These collaborations ensure that graduates are prepared well to meet the rising demands of the advanced manufacturing techniques.

“As a newcomer to additive manufacturing with close proximity to Nanyang Technological University, we were able to leverage on the talent there and start our materials development projects much earlier than if we tried to do this internally by ourselves,” said Mr William Goh, Head of Additive Manufacturing, Makino Asia.

Lifelong learning

“Learning is embedded in life and life is shaped by learning. That is the secret of lifelong learning: life and learning are intertwined. Therefore, ensuring the right to lifelong learning is not only a minimum requirement for maintaining human dignity, but also a way to maximize well-being for all,” says Director, National Institute for Lifelong Education (NILE), Republic of Korea.

Lifelong learning is crucial in rapidly evolving manufacturing landscape. Continuous education and skill upgrading for workers are being promoted by governments & companies in Asia. For instance, the SkillsFuture initiative of Singapore offers funding for individuals to pursue courses in advanced manufacturing technologies. Let us look at some of the real-time examples in countries like Japan, South Korea and South East Asia.

Commitment to innovation as well as quality is evident in Japan’s manufacturing industry. Also, the integration of robotics & IoT in manufacturing industry has enabled big players such as Sony & Toyota to maintain their global competitiveness. The focus of Japan on smart manufacturing principles has ensured continuous improvement & high standards in manufacturing.

The manufacturing industry in South Korea has transformed owing to the investments made by the country in advanced manufacturing technologies. The focus on advanced technologies such as 3D printing, robotics as well as artificial intelligence has resulted in significant advancements in the automotive & electronics manufacturing segment. Firms like Hyundai & Samsung are at the forefront of this transformation.

Southeast Asian countries are embracing digital transformation largely in the manufacturing industry. The Smart Nation Initiative of Singapore and the Thailand 4.0 policy of Thailand are perfect instances of how the region is leveraging advanced manufacturing and advanced technologies to bolster and augment manufacturing. Hence, these initiatives are not only creating new growth opportunities but they are also positioning Southeast Asia as one of the competitive hubs on the world map.